With the invention of the welding machine, it became possible to quickly obtain high-quality connections of metal parts. But progress has gone further, and created an inverter that is smaller and more beautiful, but more productive and functional. The double current transform that occurs inside it allows you to create a smooth arc and superimpose small flakes of high strength.

Such a unit is now available in every workshop and serious construction company. The capabilities of the inverter are highly dependent on the maximum and minimum values of its parameters, knowing that you will be able to purchase a reliable welding machine that meets the assigned tasks.

Content:

The best manufacturers of welding inverters - which company to choose

When an inverter is urgently needed for simple work in a private house or garage, you can safely buy the products of proven companies:

1. Fubag

2. Inforce

3. Elitech

4. Brima

5. Patriot

But due to the different performance and time use of individual models, it is worth getting acquainted with rated best welding inverterscontaining their description with advantages and disadvantages.

For the most demanding customers, a detailed analysis of the selection parameters of this welding equipment is provided.

The principle of operation and welding inverter device

An inverter differs significantly from a conventional welding machine by the difference in the frequency of the current. Both devices receive alternating voltage, but at the transformer it remains the same as in the network (50 Hz), and at the inverter it rises to 50,000-80000 Hz and is converted to a constant one. This has a great effect on the penetration of the filler metal deep into the core and forms a smooth fine-flaked seam.

Such a scheme minimizes the formation of pores upon release of carbon and increases the resistance of the created compound to kinks and rupture.

The use of inverters is quite wide, because with its help you can make:

- gate or gate in a private house;

- water tank and truck fuel tank;

- metal entrance doors;

- fence or fence;

- large greenhouse and small greenhouse;

- plumbing and heating;

- towel warmer;

- patch up the bottom of the car;

- make a crack in the engine block.

Apply welding inverters in private workshops, large enterprises and just in the country for various small works. It is irreplaceable at the construction site, especially in modern technology of monolithic-frame houses, where welding of fittings inside filler columns is required. This unit can be welded cast iron, low alloy steel, stainless steel, aluminum and copper. Transformer to do this will not work.

The inverter device includes the following elements:

- housing;

- diode bridge;

- transistors with radiators;

- transformer;

- rectifier;

- noise filters;

- current sensors;

- integral stabilizer;

- cooler;

- relay;

- contactors and control board.

To operate the device is connected to the mains voltage corresponding to its characteristics. Weight cable (-) attached to the product or the metal table on which it is located. The holder (+) is taken by the welder. An electrode is inserted into it, which is both an additive material and protects the molten metal from exposure to ambient air.

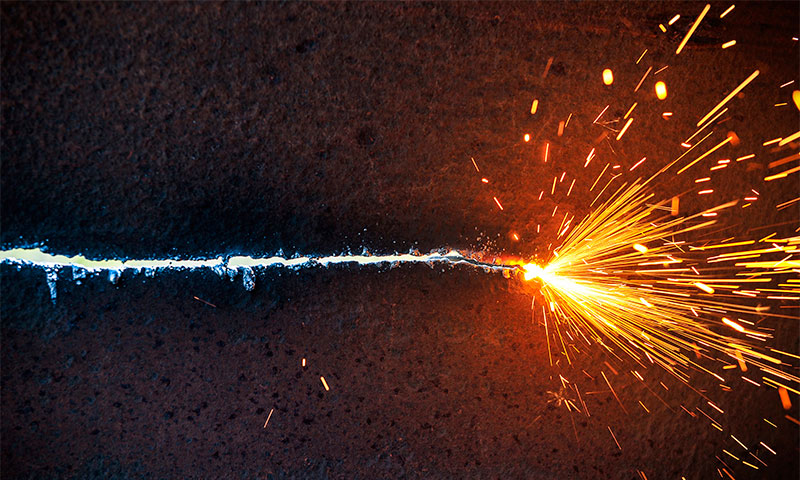

The touch of the electrode to the product produces a short circuit of the poles of the welding machine and an electric arc arises.In order to perform manipulations to create a seam, it is necessary to hold the end of the electrode at a distance of 3-5 mm from the surface. This will allow the arc to burn freely, to melt the main and filler metals and not to stick to the product.

To get a constant voltage, the current in the device passes several nodes. From the network, it goes to a rectifier consisting of diodes and a bridge. After that, a constant voltage is applied to the keys containing transistors and radiators, where its frequency increases significantly. Then the step-down transformer reduces the voltage to safe values, while simultaneously increasing the current to the value of steel capable of smelting.

Types of welding inverters

Despite the general principle of operation and the internal structure, the inverters are divided into three groups. Each has its own purpose and capabilities.

Domestic

Such devices have low cost and small size. They are distinguished by limited power and low time performance at maximum current.

Opportunities for compounding thick metals are also limited by low amperes. These inverters are suitable for infrequent work at the cottage (fix the tank with water on the shower, build a shed), during personal repairs at home (cook the railing on the balcony, attach the threaded nozzle) or in the yard (wicket, fence).

Advantages:

- small weight;

- acceptable price;

- availability of protection;

- the ability to perform basic welding work.

Disadvantages:

- current capacity is limited to 4-5 kW;

- current has a limit of 180-200 A;

- thin welding wire;

- it is impossible to connect metal less than 1 mm thick;

- It is impossible to weld with a voltage drop in the network.

Semi-professional

This equipment has increased power, which allows material to be melted faster. The performance of the models is extended and they are able to function even with a voltage drop in the network up to 165 V. They have a current of 200-300 A. Sometimes they are supplemented with a TIG welding connector.

Such models are used in car services and construction teams, where welding is not the main activity, but requires high quality.

Advantages:

- high amperes, allowing you to boil a thick metal;

- powerful;

- work even when the voltage drops;

- have a TIG connector;

- average cost.

Disadvantages:

- duty cycle is limited to 60%;

- The maximum thickness of the metal being welded is 5-6 mm.

Professional

They are distinguished by high rates of current strength, power and a long operating cycle (up to 90-100%). They can boil a very thin iron, because digital adjustment allows to reduce the current to 10 A. The device can function even when the voltage drops to 130 V.

These inverters are used for professional activities, in which you have to use the device for 6-8 hours every day (welding of heating, plumbing, towel warmers, manufacturing doors, gates, containers).

Advantages:

- current up to 300-500 A;

- duty cycle up to 80-100%;

- availability of TIG welding;

- possibility to lower amps up to 10;

- digital adjustment;

- power.

Disadvantages:

- expensive;

- weight 8-10 kg;

- short cable lengths included (must be purchased separately).

Inverter selection options

In order for the device to fully suit the owner, it is necessary to select its parameters for the required types of work and the conditions where they will be implemented. Such a correspondence will allow to get a good result and to use the inverter for a long time.

Incoming voltage

There are models that can work only from the 220 V network, which will allow them to be used at home or at the facility (apartment renovation, balcony). The 380 V devices can be powered only at the enterprise from the shield with the corresponding voltage. The presence of such a connection is possible in the garage, where there is a three-phase input. This will allow them to cook throughout the day and melt down the thick sides. But in the apartment or in the country it will be useless.

There are models with the ability to switch the incoming voltage 220/380 V, which gives greater freedom.At home or on the road, they can be plugged into an ordinary socket and boiled steel up to 5-6 mm thick, and in a production or workshop with three phases, welding of thicker structures can be performed. These units are convenient for mobile repair teams.

Ability to work at minimum voltage

Some inverters operate only from 220 V and, if the voltage drops, they begin to shorten the arc, which leads to a constant sticking of the end of the electrode. Such equipment is worth buying only if the line to which the house / garage is connected is not overloaded. You can know this if you regularly check the mains voltage with a voltmeter.

In the same place where loads and drops in a chain are possible, they buy devices with an indicator of 135-165 V, which themselves stabilize the internal voltage, which does not affect the characteristics of the arc and the quality of the seam. Such a model will be useful to both the repairman and the welder engaged in heating, who does not know the network parameters at the future place of work.

Degree of protection

The characteristics of the prescribed degree of protection of the housing of the unit, allowing to evaluate its endurance in certain situations. The parameter is indicated by the letters IP and two numbers. The first indicates protection from hitting solid objects. Often, this is the number 2, which means that the welder will not accidentally be able to stick fingers or thick fittings under the case, but dust and fine oxides will accumulate there, since there are many ventilation holes in the casing.

The second digit, in the case of inverters, can vary from 1 to 3, which means:

- no water falling vertically into the device;

- the operation of the apparatus will not be disturbed by water from above, even if the case is deflected from the vertical position by 15 degrees;

- the inverter will be able to work in the rain with oblique splashes up to 60 degrees.

If you have to work always in a dry room, then IP21 is enough. When you come across orders related to the installation of doors and gates in a private house, it is desirable to have an indicator IP22. If you often have to work on the street (welding fences, greenhouses, huge tanks), then, so that the rain does not spoil all the plans, you should purchase a model with a value of IP23.

Electrode Diameter

In everyday life, electrodes are from 1.6 to 6 mm. They are selected in accordance with the work ahead. The thicker the metal being welded, the larger must be the diameter of the electrode. If this parameter is not sustained correctly, then thin electrodes will take a very long time to seam, and thick sheet metal cannot be welded. The thicker the diameter of the electrode, the higher the current should be, which will lead to the premature melting of thin consumable elements and make it impossible for high-quality fusion.

To work with pipes (heating, plumbing) enough electrode in 3 mm. To brew a car body, 1.6-2 mm are needed. When welding sides with a thickness of 5-10 mm, a diameter of 4-6 mm is required.

Duty cycle

This is the time during which the device will be able to work continuously. It is calculated in percent, and the remaining value is required to cool the device. For example, a 70% indicator implies that the inverter will be able to cook for 7 minutes continuously, but then 3 minutes needs rest.

If the device is purchased for giving, then a model with an indicator of 60-70% is acceptable. It can be used for welding greenhouses, fence or canopy, where the fitting and installation of parts require sufficient time to cool the machine. For professional activities in welding of heating, doors, tanks, a value of 80-100% is required.

But the percentage of the time indicator implies the use of equipment at the maximum current (A). If the upper limit of the apparatus is 300 A, and work is being carried out at 200 A, then the time of uninterrupted work increases.

Power

Inverters power is measured in kW and can vary from 2.7 to 27. This is one of the performance indicators and the ability to melt more thickness. The higher the power, the thicker products you can work with. But this exerts a load on the wiring in the room, which must be of the appropriate section.

To give enough power in 2.7-3.5 kW. This will allow to brew a pipe or build a low greenhouse with tacks. Good welding is required for welding water pipes or entrance doors, so a figure of 5-7 kW is required here. In order to melt chromium alloyed boiler steel, an inverter with a power of 10-20 kW is needed, but this wiring will not withstand the house, so a three-phase input is needed.

Maximum welding current

The value is set on a digital scoreboard or scale and is calculated in amperes. It can be from 160 to 500. It is also associated with the ability to melt a certain wall thickness of the metal being joined. An insufficient amount of amps will lead to the layering of the filler metal on the surface, without penetration. Such a connection will not be very tight and fast at kink.

For example, to weld two pieces of reinforcement 6 mm you need 100-150 A. For two-inch pipes used in heating, you need 120-160 A. In metal doors with a 3 mm overlay sheet and a corner with a wall of 4 mm you need a powerful inverter for 200- 300 A. These same indicators are suitable for welding a fence or roof. The heat exchanger in the furnace, the walls of which reach 10 mm, is boiled by equipment at 400-500 A.

Min welding current

This is indicated on the same scale as the previous parameter, but in the opposite direction. There are models of inverters with a limitation in the lower limits up to 10-60 A. Small currents are necessary for working with thin iron. The inability to reduce the amperage leads to rapid overheating of the sides, their hardening and burn-throughs. Here, additional resistance from a steel spring is used, but this requires separate costs and is impractical on connections.

It is better to immediately purchase an inverter with the ability to reduce the current to the desired value. Welding a 1.2 mm thick sheet iron shower tank needs a figure of 60-80 A. The body metal of a car can be about 1 mm and it is welded to 30-40 A. You can grab even thinner sheets of metal on the frame structure by putting it on the board 10-20 A.

TIG connection

Such a function implies the possibility of disconnecting a conventional cable with a holder and inserting an argon burner in its place. The device should be provided with an additional channel for supplying gas (argon) and connecting the control buttons from the burner (if any).

Thanks to TIG, welding of non-ferrous metals is possible: stainless steel, aluminum, copper. The burner uses a non-consumable electrode (tungsten), which only excites the arc. The seam is formed by melting the edges of the joint and filler metal supplied separately from the wire. Inert gas from a cylinder provides protection from the influence of ambient air.

Such a function is useful for the manufacture of heated towel rails, welding heads from the engine block, repair of stainless arc from cars, brazing of copper. Its use requires additional costs for expensive tungsten electrodes, the purchase of a gas cylinder and its transportation. Such is the lot of professionals in these areas. For the dacha equipment it is an unclaimed item, which will cost a decent overpayment.

Current adjustment

You can adjust the number of amps using the switch on the inverter case. This is required each time when the metal thickness of the parts to be connected is changed. But the adjustment method is smooth and stepped. The first is used on expensive models, where you can set the current strength literally one by one (19-20-21-22 A). This allows you to select the optimal value that is convenient for the welder and the corresponding welded parts.

The second method involves switching with a circular toggle switch in steps of multiples of 20 A (20-40-60-80-100). This is enough for most ordinary jobs that do not require high quality, but in individual situations it may turn out that 40 A is not enough for a good penetration, and 60 already leads to burn-throughs.

Therefore, to give or welding non-critical products, you can buy inverters with a toggle switch, and working on the pipeline, making tanks for fuel or frequent welding of thin differential materials requires a digital display and smooth switching.

No-load voltage

In the on state, but before the moment of excitation of an electric arc, the inverter is idling. It can be from 40 to 90 V and is responsible for the rapid contact between live parts and ease of ignition. The higher the score, the better it works. When the electrode closes on a surface connected to ground, the voltage automatically decreases to a safe value of 12 V.

For beginners, it is difficult to properly ignite the arc and keep it at a certain distance, so it often goes dead in them and requires re-ignition. Here it is practical to use equipment with a 70-90 V index for convenient operation. Skilled craftsmen of such a large amount of idling is not required, because this is due to the increased consumption of electricity during downtime, and models with 40-60 V.

Weight

The weight of the inverter can be from 2.5 to 10 kg. It depends on its power and configuration, but the mass itself affects the usability in certain conditions. For example, when moving frequently around the object, 10 kg is tiring for the welder and harmful to the hand, which should not tremble during the stitching. Here we need models weighing 5-6 kg.

If you have to cook a high greenhouse or support under the power line, you need a very lightweight model of 3 kg, which can be hung on the belt by the shoulder. For stationary actions in the garage will fit any mass.

Wire length

Complete with inverters are sold weight cable and holder. Their length is from 1.5 to 1.8 m. This is enough for small work on the table, welding the fence or heating, where the device can always be pulled closer. But the manufacture of large capacity or stitching on the greenhouse require elongated cables in order not to overload the equipment, therefore, an additional wire of 2.5-3 m is chosen.

Additional functions

Some jobs are more convenient to do with additional features, such as Hot Start. This allows you to avoid the procedure of burning the electrode and immediately proceed to the imposition of a seam. This feature is useful for beginners or where high quality products with minimal traces of welding contacts are required.

The arcforce allows you to momentarily increase the voltage, regardless of the set values, when the device “feels” the electrode sticking. This is useful for inexperienced hands or welding on very thin metal.

Which inverter to choose

After considering the parameters of welding inverters, you can select specific values for various uses:

1. A simple device to the country, for welding a fence or tank, will have a power of 2.5 kW, protection class IP21, operating from 220 V and having a cycle of 60%. The current range will range from 40 to 180 A. The cable length is 1.5 m, and weight up to 3 kg. Beginners arc very useful for beginners.

2. The device for welding plumbing and heating needs an IP23 protection class, a run-up setting of amperage from 30 to 250 A, with 220 V power supply, 3-5 kg weight, 6-7 kW power, supporting work with electrodes from 2 to 5 mm diameter , smooth switching, a cycle of 70% and a cable of 1.8 m. The device should continue to work freely even when the voltage drops to 160 V.

3. Welding cracks in the engine head, pallets or other auto repair will require the TIG function, with a current range of 20-300 A, power from 220/380 V, IP22 protection class, 60-80% cycle, digital display and 8 kW power.

4. Making boilers or connecting thick beams at a construction site is possible with an apparatus with a power of 20 kW, powered from a mains 380 V, weighing 10 kg, a cycle of 80-100%, a run-up amperes from 40 to 500, welding electrodes supporting a diameter of 2-6 mm and a long cable , 5 m. The protection class will require IP23, designed for outdoor conditions.

How much does a welding inverter cost

Knowing the parameters of the equipment, it is easy to find its approximate cost, which can vary depending on the company and the country of origin:

1. Inverter to the country costs 4000-8000 rubles.

2. The device for welding of heating can be bought for 6000-12000 rub.

3. To work in the service station or with non-ferrous metals will need to pay for the equipment 14000-38000 rubles.

4. Boil thick steel can be a device for 17000-40000 rubles.

It will be interesting to friends too