Pipe benders allow bending round and square pipes at different angles to create smooth turns when laying water communications, heating, frame structures. The equipment is divided according to the size of the support rollers and the ability to work with blanks of a certain diameter. Their use covers production workshops, the production of water pipes and heating systems for off-site work, forging, installation of metal structures. From our ranking of the best benders you can see the already proven equipment of manual, hydraulic and electric types, which will facilitate the choice of model and type for a particular activity.

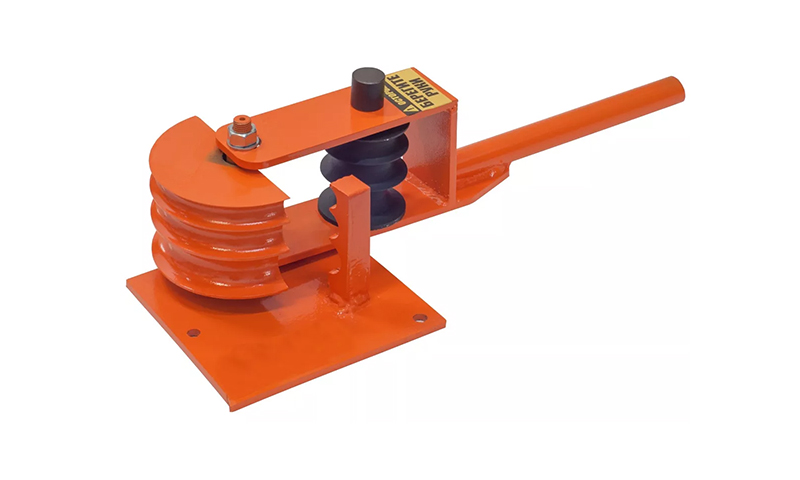

The best manual pipe benders

This equipment is driven by the operator and allows you to bend workpieces with a diameter of up to 32 mm.

Ease of use depends on the length and shape of the lever. The pipe bender needs to be fixed on a rigid base. It is used for off-site installation work and in small-scale production of products from pipes.

Stalex TR-10 100308 - reasonable price and quality

This pipe bender is the best for a small enterprise or in the manufacture of products in a personal workshop due to the affordable price of 4900 rubles and the ability to work with three pipe diameters without rearranging the tooling.

The design immediately incorporated three variants of the frame with the corresponding cutouts on the rollers, and a high emphasis for clamping the end of the part. On the platform there are three holes for mounting equipment on the workbench.

The tool was made of tool steel and painted with powder coating, which permanently protects against corrosion.

Pros:

- cost from 4900 rubles;

- axis on which the matrix rotates, from a thick bolt;

- reinforced frame of steel with a thickness of 6 mm;

- the ability to work with different diameters of pipes without changing rollers, because everything is installed immediately;

- suitable for workpiece diameters of 20, 25 and 32 mm;

- arches up to 180 degrees;

- compact dimensions of 610х270х195 mm easily fit in the trunk for transportation to the place of installation;

- acceptable weight 15 kg for field work.

Minuses:

- a short handle needs lengthening to make it easier to bend;

- Welding seams are of poor quality, so before prolonged use you should digest them again;

- the holes for fixing the platform with a diameter of 10 mm, and according to the instructions of the same tool it is necessary to fix it with M12 bolts, so you will need to drill out;

- The central hole on the platform is close to the matrix form and may interfere with work with a pipe diameter of 32 mm (you need to think about where to move this mount).

Smart & Solid BendMax-200 - for profile

This is the best manual pipe bender for working with square or rectangular parts, because it is assembled from thick steel, which serves as a key element in withstanding loads during bending.

The stops are two rollers at the bottom, and the third is provided with a crank handle for rolling the part. The beating is carried out by the gradual pressing of a mechanically driven screw. On the front side of the case a scale is glued to determine the bend angle.

Pros:

- robust thick steel housing;

- comfortable plastic handle winding knob for rolling parts;

- hardened steel on casters with a hardness of 42-48 HRC;

- can be used without fixing on the workbench;

- suitable for profile bending, cast square;

- the housing is disassembled by unscrewing the bolted connections, which provides access for repair;

- the course of the screw is clearly controlled by two nuts;

- compact dimensions 230x440x460 mm;

- You can bend a pipe with a diameter of 15x15 mm to 40x40 mm;

- copes with a thick section of the wall of the workpiece to 2 mm;

- even suitable for steel St3.

Minuses:

- cost from 13,400 rubles;

- the screw drive is inconvenient for tightening due to the thin rod and the absence of large stops on the ends;

- when pressing the workpiece is indented into the notch;

- weight 23 kg

Top hydraulic pipe benders

Such a tool has similar structural elements, but the drive is carried out like on a jack, which allows working with a large diameter of pipes, an increased cross section of the wall and less application of own forces to the operator. It is used on construction sites and when laying water communications.

STELS 18115 - for plumbing and heating

This is the best pipe bender for quick turnaround when laying plumbing or heating, because the device comes in a plastic case, convenient for transportation, and is able to work with parts of different diameters thanks to four interchangeable holes in the case for rollers and three shoes in the kit.

Due to the hydraulic drive, the master will be able to quickly make the required number of knees to create turns in the water supply system.

Pros:

- the cost of 7,500 rubles is acceptable for this category of equipment;

- you can work without fixing on the workbench;

- durable metal frame withstands heavy loads and is not deformed;

- simple change of shoes for different pipe diameter;

- springs on the rod help to quickly return the extended element in place for the installation of the next workpiece;

- compact dimensions of the fixture 540x530x190 mm;

- on stock up to 8 tons;

- suitable for ½, ¾, and inch pipes;

- case included.

Minuses:

- a large mass of 25 kg;

- no scale of degrees are flexible;

- bend angle only up to 90 degrees.

SWG-2 RENZA 068-1062 - for thick pipes

This is the most popular pipe bender for self-bending thick pipes, because its frame allows to put in it blanks with a diameter of up to 50 mm.

On the case there are 6 holes for rearranging the rollers, so the giant will be able to bend a thin piece ½ inch. In addition, the design has a support tripod on wheels, which is convenient for transportation on a flat floor without additional accessories.

Pros:

- the convenient rubberized handle on the lever;

- quick swapping of the rollers by taking out the locking fingers;

- a separate tripod eliminates the need for a workbench;

- high-quality powder coating;

- stroke rod 250 mm;

- 6 nozzles of shoes included;

- able to bend workpieces with a diameter of 50 mm;

- does not deform the walls;

- high-quality seams on the body.

Minuses:

- cost from 20,900 rubles;

- weight 52 kg;

- bend angle is limited to 90 degrees.

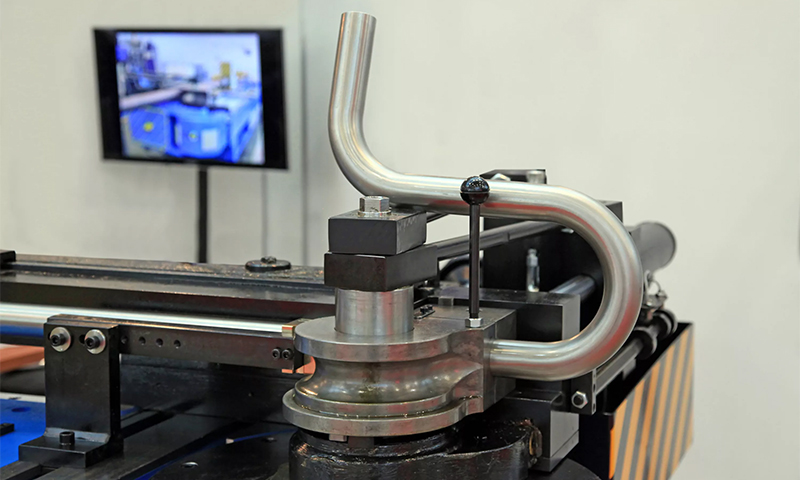

Best electric pipe benders

Such equipment is used for a large amount of work, because the operator does not use his own power at all - all the action is performed by an electric motor and gearbox.

Adaptations are suitable for both the production of serial plumbing products on a large scale, and for the manufacture of forged products.

Blacksmith ETB40-50HV - vertical model for artistic forging

This is the best electric pipe bender due to the presence of two drive shafts with a rotation speed of 18 revolutions per minute, which indicates high performance.

The control is performed by the pedals, so the hands of the operator are free to quickly change the blanks or to hold the edge to give a certain shape.

The machine has a vertical location. The course of the pressure roller is performed manually. To instantly stop the operation, there are two emergency buttons: on the case and on the stand with the pedals.

Pros:

- universal form of rollers for the bending of a square, a profile and round pipe, strips of metal, corners;

- it is calculated on the maximum diameter to 42 mm;

- copes with a wall thickness of 2.5 mm;

- plastic stops on the screw drive;

- effective work due to the speedy pressing of the roller and reducing the number of cycles;

- convenient control of foot pedals;

- holes in the base for securing the machine to the floor and increasing stability;

- due to the vertical performance does not take up much space in the workshop and the operator is comfortable working while standing.

Minuses:

- cost from 165,000 rubles;

- weight 230 kg is difficult to transport;

- connections need a 380 V three-phase network;

- manual movement of the pressure roller.

It will be interesting to friends too